Samar da Margarine ya haɗa da sassa biyu: shirye-shiryen albarkatun ƙasa da sanyaya da filastik. Babban kayan aikin ya haɗa da tankunan shirye-shirye, famfo HP, masu jefa kuri'a (mai canza yanayin zafi), injin rotor, sashin firiji, injin margarine da sauransu.

Tsarin da ya gabata shine cakuda lokacin mai da lokacin ruwa, ma'auni da cakuda emulsification na lokacin mai da lokacin ruwa, don shirya kayan abinci na ƙarshe. Tsari na ƙarshe shine ci gaba da sanyaya plasticizing da marufi na samfur.

Ana nuna tsarin shirya albarkatun kasa na margarine a cikin hoto 1:

1.Madara mai taki

Wasu nau'in margarine don ƙara madara, da madara bayan kwayoyin lactic acid fermentation na iya samar da irin wannan dandano na kirim na halitta, don haka masana'anta zuwa madarar fermented da ruwa gauraye.

2.Haɗin ruwa

Ruwa da abubuwan da ke narkewar ruwa a cikin tsarin margarine, kamar madara mai ƙwanƙwasa, gishiri, abubuwan kiyayewa, da sauransu, ana ƙara su zuwa ga hadawar lokaci na ruwa da tankin metering a cikin ƙayyadaddun ƙayyadaddun ƙayyadaddun don motsawa da haɗuwa, ta yadda lokacin ruwa ya zama. aka narkar da aka gyara a cikin wani uniform bayani.

3.Haɗin lokaci mai

An fara hada danyen mai na wasu bayanai dalla-dalla a cikin tankin hadakar mai daidai gwargwado, sa'an nan kuma ana kara abubuwan da za su iya narkewa kamar su emulsifier, antioxidant, pigment mai narkewa, cellulose mai narkewa, da sauransu. da man fetur bisa ga rabo, gauraye da metering tank, da kuma zuga zuwa samar da uniform lokaci man.

4. Emulsion

Manufar emulsification na margarine shine don sanya lokaci mai ruwa da tsaki a ko'ina kuma ya watse a cikin lokacin mai, kuma matakin watsawa na lokaci mai ruwa-ruwa yana da babban tasiri akan ingancin samfurin. Saboda dandano na margarine yana da alaƙa da girman nau'in ɓangarorin ruwa, ana aiwatar da yaduwar ƙwayoyin cuta a cikin lokacin ruwa, girman ƙwayoyin cuta na gabaɗaya shine 1-5 microns, don haka raguwar ruwa a cikin 10-20. microns ko ƙananan kewayo na iya iyakance yaduwar ƙwayoyin cuta, don haka watsawar lokaci na ruwa yayi kyau sosai, ɓangarorin lokacin ruwa sun yi ƙanƙanta zai sa margarine ya rasa dandano; Watsawa bai wadatar ba, barbashi na ruwa ya yi girma sosai, zai sa margarine ya lalata metamorphism. Dangantakar da ke tsakanin matakin watsawar lokaci mai ruwa a cikin margarine da yanayin samfurin shine kamar haka:

| Girman digon ruwa (Micrometer) | Ku ɗanɗani margarine |

| kasa da 1 (kimanin 80-85% na lokacin ruwa) | Mai nauyi da ɗanɗano kaɗan |

| 30-40 (kasa da 1% na ruwa lokaci) | Kyakkyawan dandano, mai sauƙin zama mai lalacewa |

| 1-5 (kimanin 95% na lokacin ruwa) | Kyakkyawan dandano, ba sauƙin zama mai lalacewa ba |

| 5-10 (kimanin 4% na lokacin ruwa) | |

| 10-20 (kimanin 1% na lokacin ruwa) |

Ana iya ganin cewa aikin emulsification ya kamata ya kai wani mataki na buƙatun watsawa.

Manufar hadawa da ruwa lokaci da kuma man lokaci dabam kuma a ko'ina tare da kafin lokaci shi ne don tabbatar da uniform daidaito na dukan emulsion bayan emulsification da cakude na man fetur da ruwa matakai biyu. Emulsification hadawa ne, da aiki matsalar ne 50-60 digiri, da ruwa lokaci da aka kara zuwa auna man lokaci, a cikin inji stirring ko famfo sake zagayowar stirring, ne ruwa lokaci cikakken tarwatsa a cikin man lokaci, samuwar latex. Amma irin wannan ruwan latex yana da matukar rashin kwanciyar hankali, dakatar da motsawa na iya kasancewa akan filin wasan mai da yanayin rabuwar ruwa.

Bayan an isar da emulsion ɗin da aka haɗe, ana aiwatar da tsarin sanyaya da filastik har sai an haɗa samfurin.

Dole ne a sanyaya emulsion da filastik don samar da samfurin margarine mai sassauƙa. A halin yanzu, galibi yana ɗaukar na'urar da ke ci gaba da kashewa, gami da masu jefa ƙuri'a ko ake kira mai canza zafi mai zafi (raka'a A), na'ura mai juyi ko na'urar kneading (raka'a C) da bututun hutawa (raka'a B). Ana nuna tsarin fasaha a cikin hoto 2:

Wannan saitin kayan aiki yana da halaye masu zuwa:

1. Babban matsa lamba iska ci gaba da aiki

The premixed emulsion ana ciyar da a cikin quench Silinda ta wani babban matsa lamba famfo ga votator. Babban matsa lamba na iya shawo kan juriya a ko'ina cikin naúrar, ban da aikin matsa lamba na iya sa samfurin ya zama bakin ciki da santsi. Rufe aiki na iya hana iska da iska saboda quenching da condensation na ruwa gauraye da emulsion, tabbatar da samfurin kiwon lafiya bukatun, rage asarar refrigeration.

2. Quenching da emulsification

Ana kashe emulsion tare da ammonia ko Freon a cikin masu jefa kuri'a don kwantar da emulsion cikin sauri, don samar da ƙananan ƙwayoyin crystalline, gabaɗaya 1-5 microns, don dandano yana da laushi. Bugu da kari, da scraper a kan juyi shaft a cikin votator ne a hankali alaka da ciki bango na Silinda, don haka scraper a cikin aiki ba zai iya kawai ci gaba da goge crystallization manne da ciki bango, amma kuma sa emulsion tarwatsa saduwa da emulsification bukatun na sautin.

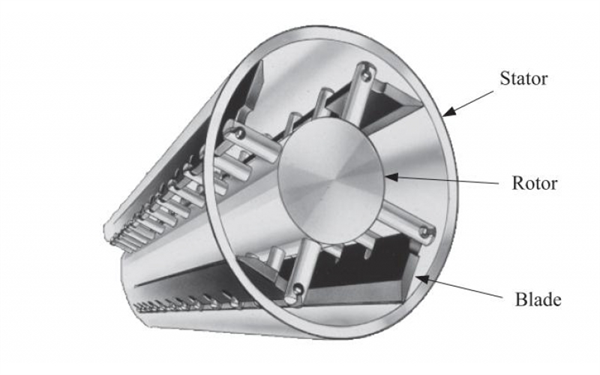

3. Kneading da dethickening (pin rotor inji)

Kodayake emulsion da aka sanyaya ta mai jefa kuri'a ya fara samar da crystallization, har yanzu yana buƙatar girma ta wani lokaci. Idan emulsion aka yarda da crystallize a sauran, cibiyar sadarwa na m lipid lu'ulu'u zai samar. Sakamakon shi ne cewa emulsion da aka sanyaya zai samar da taro mai wuyar gaske ba tare da filastik ba. Sabili da haka, don samun samfuran margarine tare da wasu filastik, tsarin cibiyar sadarwa dole ne a karye ta hanyar injina kafin emulsion ya samar da tsarin tsarin cibiyar sadarwa gabaɗaya, don cimma tasirin rage kauri. Kneading da de-thickening yawanci ana yin su a cikin injin rotor na fil.

Unit A (mai jefa kuri'a) ainihin na'urar sanyaya ce mai goge baki. Ana fitar da emulsion cikin rufaffiyar naúrar A (mai jefa ƙuri'a) ta famfon mai ƙarfi. Kayan yana wucewa ta tashar tsakanin silinda mai sanyaya da jujjuyawar juyi, kuma yawan zafin jiki yana raguwa da sauri ta hanyar kashe matsakaicin sanyaya. An shirya layuka biyu na scrapers a saman shaft. Lu'ulu'u da aka kafa akan saman ciki na mai jefa ƙuri'a ana goge su ta wurin jujjuyawar jujjuyawar sauri mai tsayi don a koyaushe fallasa sabon yanayin sanyaya da kula da ingantaccen canjin zafi. Ana iya tarwatsa emulsion a ƙarƙashin aikin scraper. Lokacin da kayan ya wuce ta naúrar A (mai jefa kuri'a), yawan zafin jiki ya ragu zuwa digiri 10-20, wanda ya fi ƙasa da wurin narkewa na mai. Duk da cewa man ya fara yin kyalkyali, amma har yanzu bai samu tsayayyen yanayi ba. A wannan lokacin, emulsion yana cikin yanayin sanyaya kuma yana da ruwa mai kauri.

Matsakaicin jujjuyawar naúrar A (mai jefa ƙuri'a) tana da rami. A lokacin aiki, ana zubar da ruwan zafi na digiri 50-60 a cikin tsakiyar axis na juyawa don hana crystallization bonded da warkewa a kan axis kuma haifar da toshewa.

Unit C (na'urar rotor fil) tana durƙusa kuma tana cire kauri, kamar yadda aka nuna a hoton da ke sama. An sanya layuka biyu na ƙwanƙolin ƙarfe a kan sandar ɗin da ke juyawa, sannan an sanya jeri na tsayayyen ƙullun ƙarfe a bangon ciki na Silinda, wanda aka yi ta tururuwa tare da ƙwanƙolin ƙarfe a kan sandar kuma ba sa taɓa juna. Lokacin da jujjuyawar ke jujjuya a cikin babban gudu, ƙwanƙolin ƙarfe a kan shingen ya wuce tazarar ƙayyadaddun ƙwanƙolin ƙarfe, kuma kayan ya cika kneded. A karkashin wannan aikin, zai iya inganta ci gaban lu'ulu'u, lalata tsarin cibiyar sadarwa na crystal, samar da lu'ulu'u masu katsewa, rage daidaito, da ƙara yawan filastik.

Unit C (na'urar rotor fil) kawai tana yin tasiri mai ƙarfi a cikin babban sanyin dare, don haka yana buƙatar adana zafi kawai kuma baya buƙatar sanyaya. Yayin da aka fitar da zafin crystallization (kimanin 50KCAL/KG), da zafin da ke haifarwa ta hanyar murƙushewa, zafin fitarwa na naúrar C (pin rotor macjhine) ya fi na zafin abinci. A wannan lokacin, crystallization yana kusan 70% cikakke, amma har yanzu yana da taushi. Ana fitar da samfurin ƙarshe ta hanyar bawul ɗin extrusion, kuma zai zama da wahala bayan wani lokaci.

Bayan an aika da margarine daga naúrar C (na'urar rotor fil), yana buƙatar a yi masa magani a wani zafin jiki. Gabaɗaya, ana sanya samfurin a zafin jiki na digiri 10 ƙasa da wurin narkewa fiye da sa'o'i 48. Ana kiran wannan maganin ripening. Ana iya aika samfurin da aka dafa kai tsaye zuwa masana'antar sarrafa abinci don amfani.

Lokacin aikawa: Oktoba-14-2022