Tsarin samar da margarine ya ƙunshi sassa biyar: lokacin mai tare da shirye-shiryen emulsifier, lokaci na ruwa, shirye-shiryen emulsion, pasteurization, crystallization da marufi.Ana dawo da duk wani abin da ya wuce gona da iri ta hanyar ci gaba da aikin sake aiki zuwa tankin emulsion.

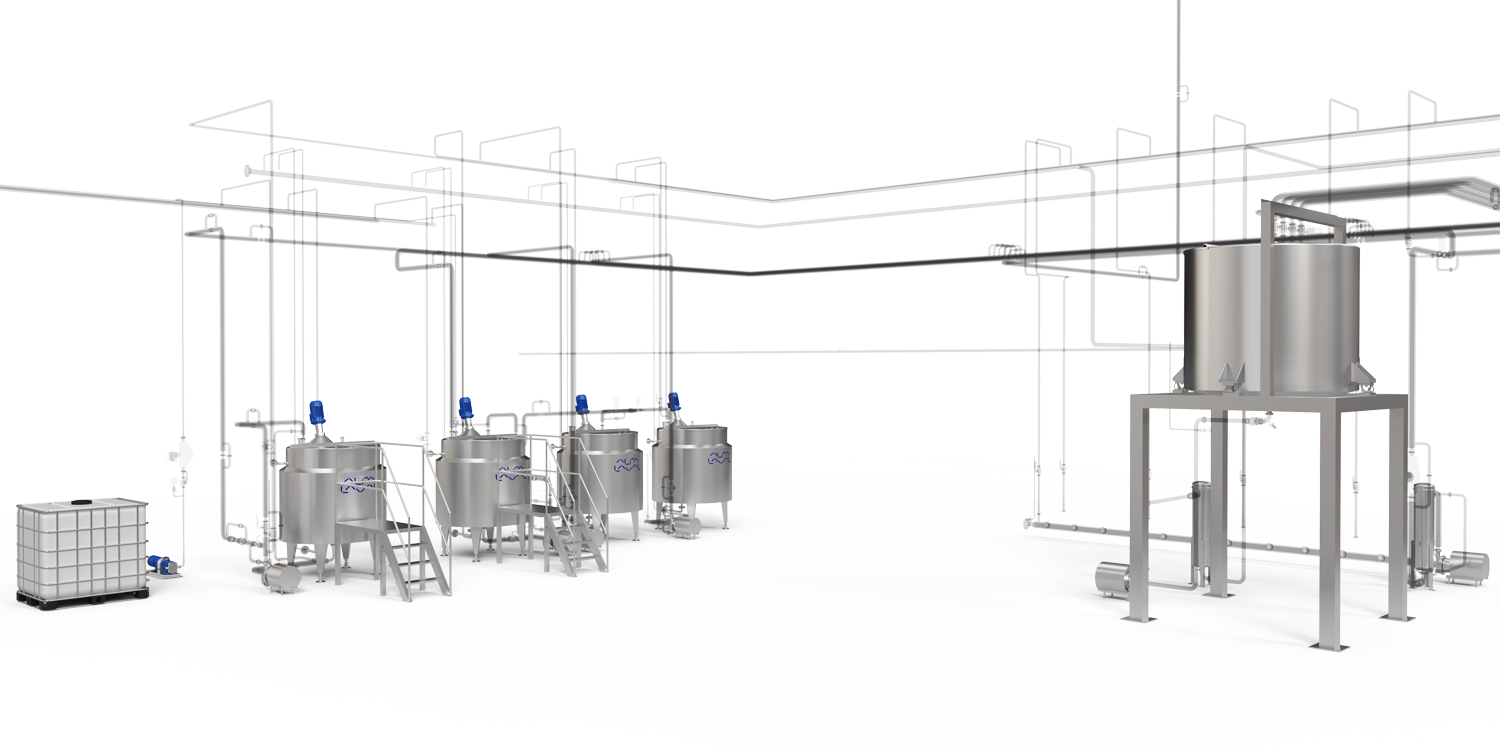

Tsarin mai da shirye-shiryen emulsifier a cikin samar da margarine

Famfu yana canja mai, mai ko gauraye mai daga tankunan ajiya ta hanyar tacewa zuwa tsarin nauyi.Don samun madaidaicin nauyin mai, an shigar da wannan tanki a sama da ƙwayoyin kaya.Ana gauraya man da ake hadawa bisa ga girke-girke.

Ana yin shirye-shiryen Emulsifier ta hanyar haɗa mai tare da emulsifier.Da zarar mai ya kai zafin jiki na kusan 70 ° C, abubuwan da ke cikin emulsifiers irin su lecithin, monoglycerides da diglycerides, yawanci a cikin foda, ana saka su da hannu a cikin tankin emulsifier.Za a iya ƙara wasu sinadarai masu narkewar mai kamar launi da ɗanɗano.

Tsarin ruwa a cikin samar da margarine

Ana ba da tankunan da aka keɓe don samar da yanayin ruwa.Mita mai gudana yana alluran ruwa zuwa cikin tanki inda aka yi zafi zuwa zafin jiki sama da 45ºC.Za'a iya ƙara busassun kayan abinci irin su gishiri, citric acid, hydrocolloids ko foda madarar da aka cire a cikin tanki ta amfani da kayan aiki na musamman kamar mahaɗar mazurari.

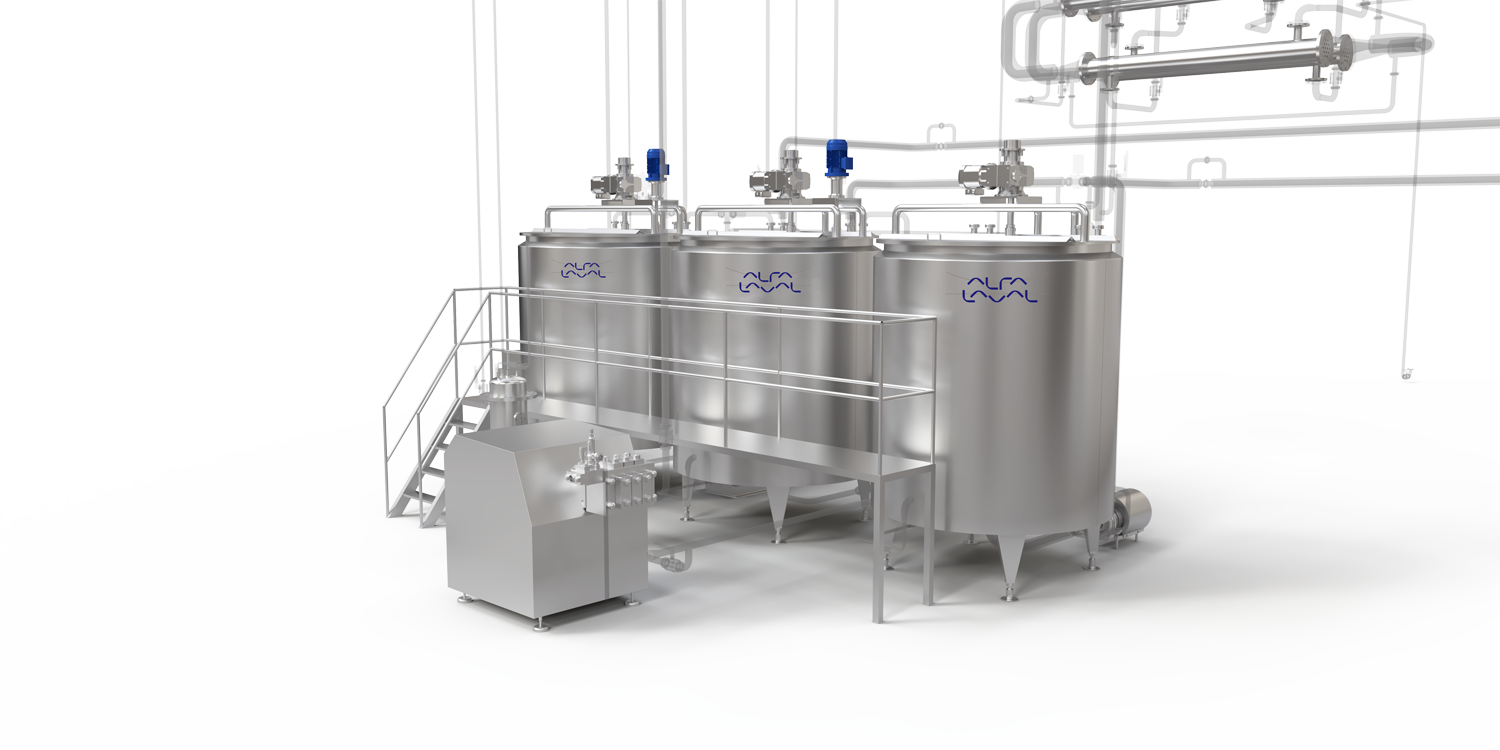

Shirye-shiryen emulsion a cikin samar da margarine

Ana shirya emulsion ta hanyar dosing mai da mai tare da gauraya emulsifier da lokacin ruwa a cikin wannan tsari.Cakuda lokacin mai da lokaci na ruwa yana faruwa a cikin tankin emulsion.Anan, ana iya ƙara wasu sinadarai, kamar ɗanɗano, ƙamshi da launi, da hannu.A famfo yana canja wurin sakamakon emulsion zuwa tankin ciyarwa.

Ana iya amfani da kayan aiki na musamman, irin su babban mahaɗar shear, a wannan mataki na tsari don yin emulsion mai kyau, kunkuntar da matsa lamba, da kuma tabbatar da kyakkyawar hulɗa tsakanin lokacin man fetur da lokacin ruwa.Sakamakon kyakkyawan emulsion zai haifar da margarine mai inganci wanda ke nuna kyakkyawan filastik, daidaito da tsari.

A famfo to tura emulsion zuwa pasteurization yankin.

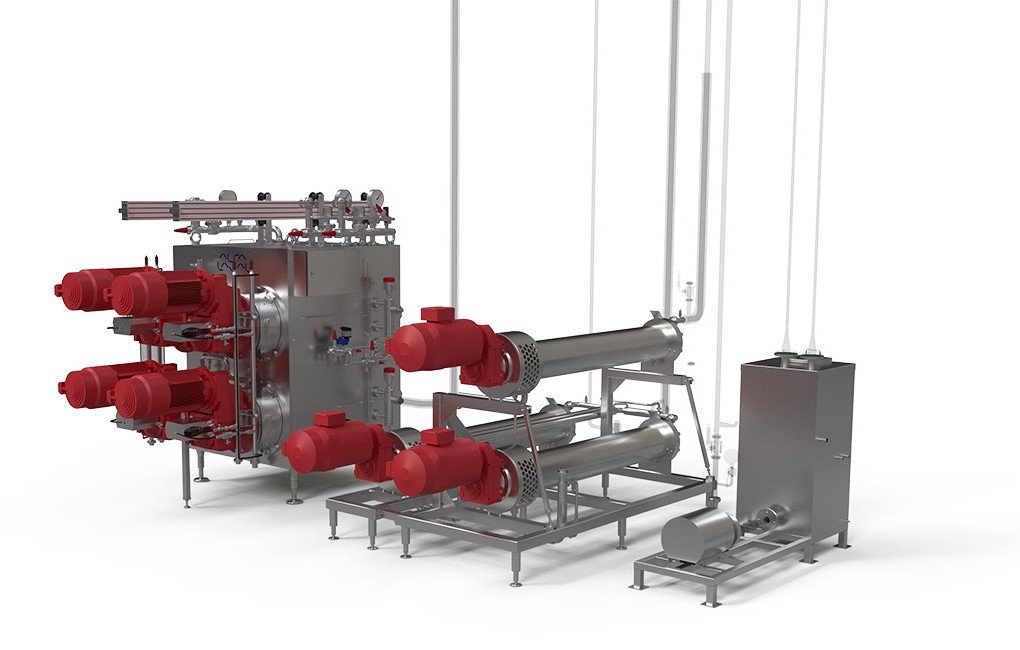

Crystallization a cikin samar da margarine

Babban famfo mai matsa lamba yana canja wurin emulsion zuwa babban matsi mai zafi mai zafi mai zafi (SSHE), wanda aka saita bisa ga yawan kwarara da girke-girke.Za a iya samun bututun sanyaya daban-daban masu girma dabam da saman sanyaya daban-daban.Kowane silinda yana da tsarin sanyaya mai zaman kansa wanda aka yiwa refrigerant (yawanci ammonia R717 ko Freon) allurar kai tsaye.Bututun samfur suna haɗa kowane silinda da juna.Na'urori masu auna zafin jiki a kowane kanti suna tabbatar da sanyaya mai kyau.Matsakaicin ƙimar matsa lamba shine mashaya 120.

Dangane da girke-girke da aikace-aikacen, emulsion na iya buƙatar wucewa ta raka'a ɗaya ko fiye da ma'aikatan fil kafin shiryawa.Ƙungiyoyin ma'aikatan fil suna tabbatar da daidaitaccen filastik, daidaito da tsarin samfurin.Idan an buƙata, Alfa Laval na iya ba da bututun hutawa;duk da haka, yawancin masu samar da injuna suna ba da ɗaya.

Naúrar sake aiki na ci gaba

An ƙirƙiri naúrar sake aiki mai ci gaba don sake narke duk abin da ya wuce gona da iri wanda ya wuce injin tattarawa don sake sarrafawa.A lokaci guda, yana kiyaye injin tattarawa daga kowane matsi na baya da ba a so.Wannan cikakken tsarin ya ƙunshi na'urar musayar zafi da farantin karfe, famfo mai jujjuyawa mai zafin rai, da na'urar dumama ruwa.

Lokacin aikawa: Juni-21-2022